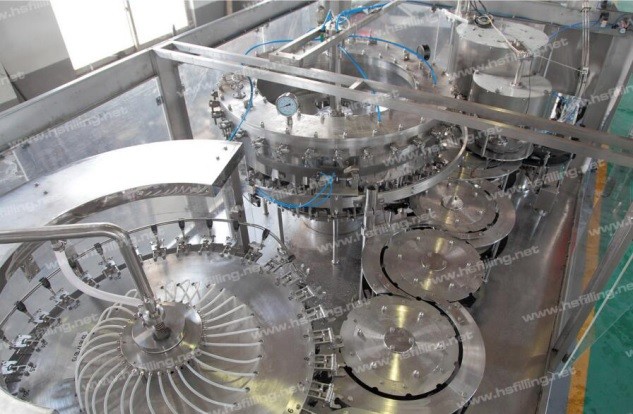

CSD bottling Monobloc Rinser Filler Capper automatic stainless

steel CE

Carbonated Soft Drink Filling Machine and Capping machine of

automatic beverage production line.

Carbonated beverage filling machines also called isobaric filling

machines; mainly used for producing Carbonated beverage; since

carbon dioxide gases(CO2) are pressurized to mix with liquids , the

pressure throughout the filling system is typically 0.3 Mpa-0.6Mpa.

and because CO2 is more stable at low temperatures, low

temperatures increase the solubility of CO2 in water. To increase

the amount of carbon dioxide dissolved in water, the beverage is

usually mixed and filled at 0-5℃.

The main factors affecting CO2 content in carbonated beverages :

1 The content of CO2 in the beverage is an important measure of the

quality of carbonated drinks; the more CO2 content in the beverage,

the more gas contain, the consumer's stronger sense of mouth brake.

The production process of Carbonated beverage is relatively complex

and has high requirements for mechanical equipment and production

conditions

2 The temperature of carbonated drinks mixing and filling: because

carbon dioxide will be more stable at low temperature, the

solubility in water is obviously increased, so the lower the

filling temperature is more favorable to the dissolution of carbon

dioxide and remain stable.

3 Carbon dioxide mixing equipment: usually produce carbonated

drinks, which match the isobaric filling system with a beverage

carbonator machine; mix carbon dioxide gas with liquid before

filling; in addition the mixing temperature, mixing pressure also

has a big impact on carbon dioxide volume, usually the carbonator

mixer has the function of mixing pressure adjustment; at the same

mixing pressure, the carbonator structure and production process

also has a great impact; carbonator mixing need to spray the liquid

out, the better the spray effect of liquid atomization, the larger

area of liquid contact gas, the better mixing effect. The liquid is

degassed before mixing. can also increase the amount and stability

of carbon dioxide dissolved in water.

4 Due to the Filling machine tank top and bottom flat, and big in

diameter, complex structure; simply said filling tank material must

have enough thickness to withstand the pressure in the cylinder;

filling tank and filling valve sealing must be good.

5 the carbonator mixed materials send into the filling tank, and

then filled into bottle, the whole process of material flow should

be stable, not due to pressure difference caused uneven flow and

impact.

6 beverage formula can also affect the amount of CO2 dissolution,

such as more syrup containing drinks, high protein content of

drinks, and fermented drinks are easy to creat foam, CO2 content

improved the foam creating. The plenty of foam creating will makes

bottle can not be full filled or crazy overflow.

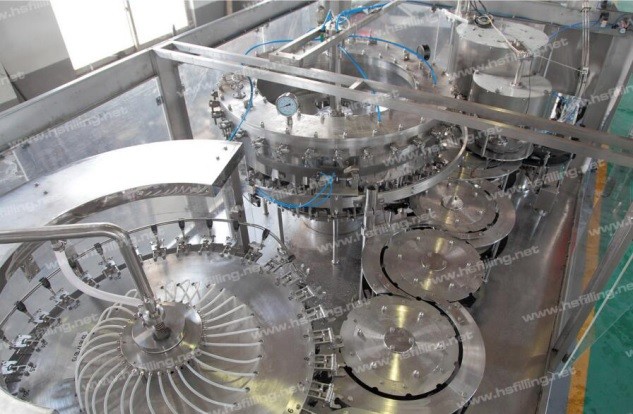

Main Parameters:

| Capacity | 10000-12000B/H(500ml) |

| Rinsing Head | 32 |

| Filling Heads | 32 |

| Capping Heads | 10 |

| Bottle Type | PET bottle Plastic screw Cap |

| Bottle Diameter | φ50-φ95mm |

| Bottle Height | 120-310mm |

| Cap Diameter | 26-30mm |

| filling temperature | 0-5 ℃ |

| Filling Pressure | 0.25-0.5Mpa |

| Level precision | ±2mm |

| Rinsing presure | 0.18-0.25Mpa |

| |